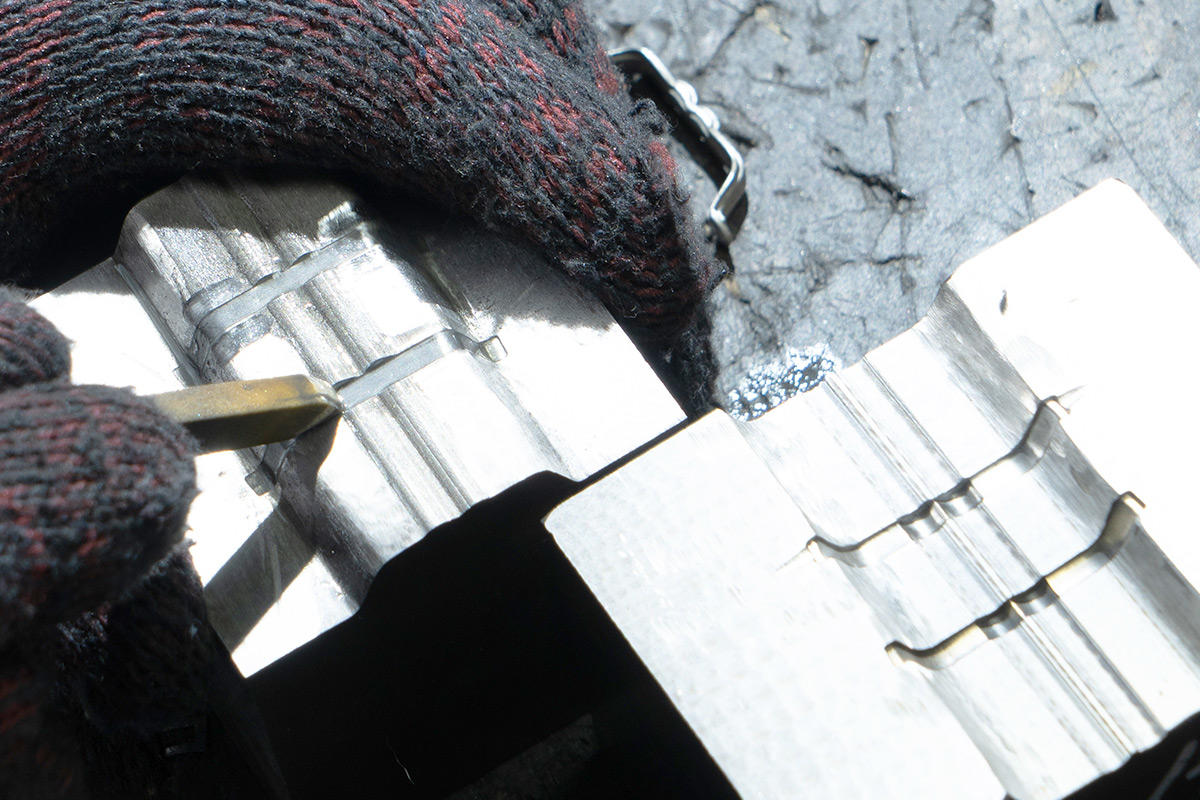

Rough rolling process

Put 6 # walnut kernels into the drum machine, add an appropriate amount of crude oil for mixing, install the shelf on the hanger, and put them into the drum. According to the frame shape and material, the corresponding time and speed shall be made to roll off the pockmarks and dead corners on the surface of the whole lens frame.

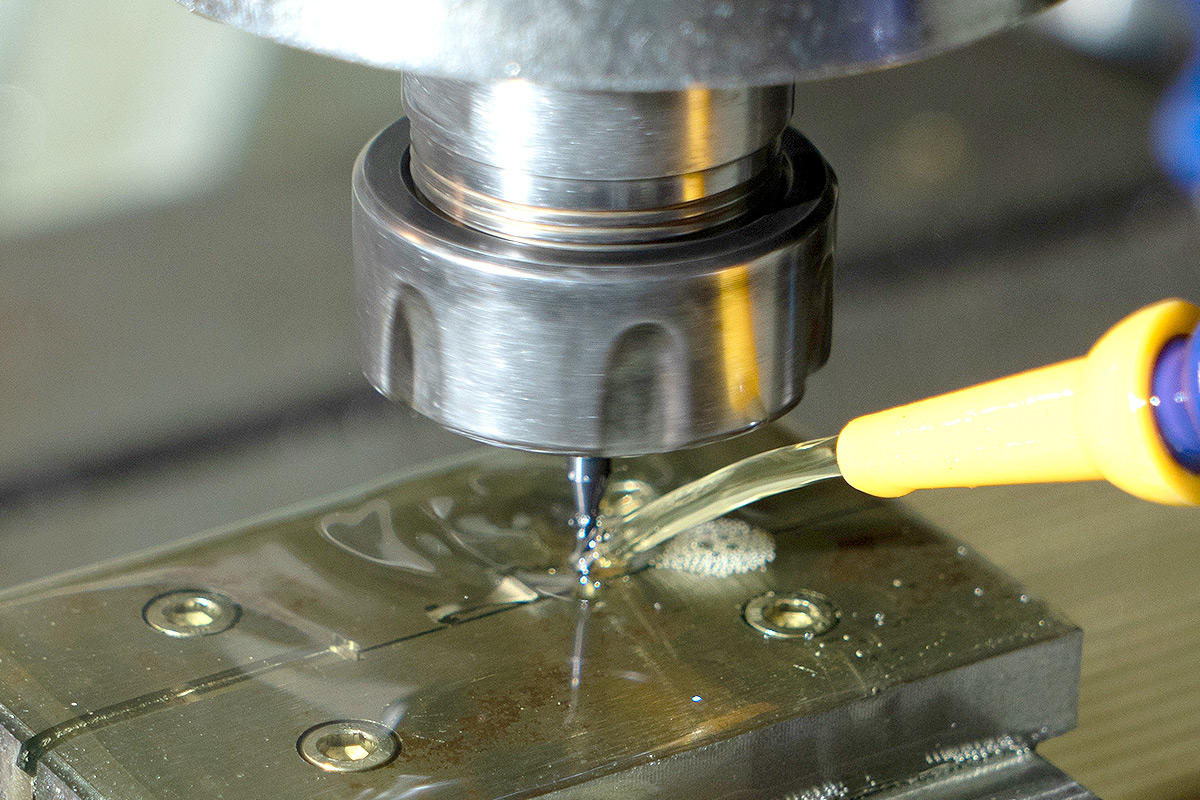

Smooth rolling process

Use 16 walnut kernels to put the roughly rolled shelf into the smooth rolling machine, add an appropriate amount of varnish to stir, and then put the shelf into the smooth rolling machine for 10 hours. Make the gloss of the surface of the pay rack uniform, so that there will be no two colors in the subsequent electroplating.

Search

Search EN

EN English

English Deutsch

Deutsch Français

Français Español

Español italiano

italiano cn

cn jp

jp kr

kr