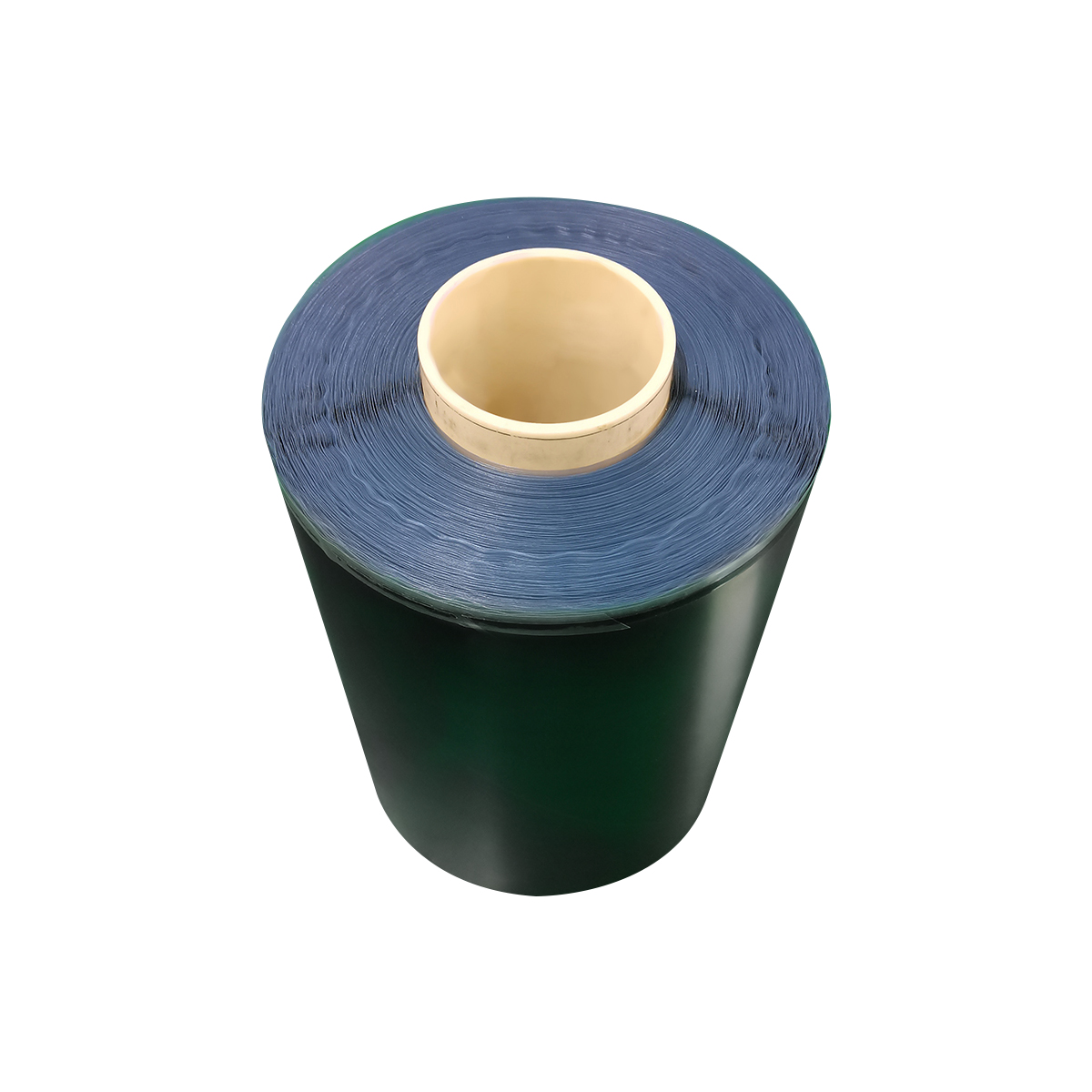

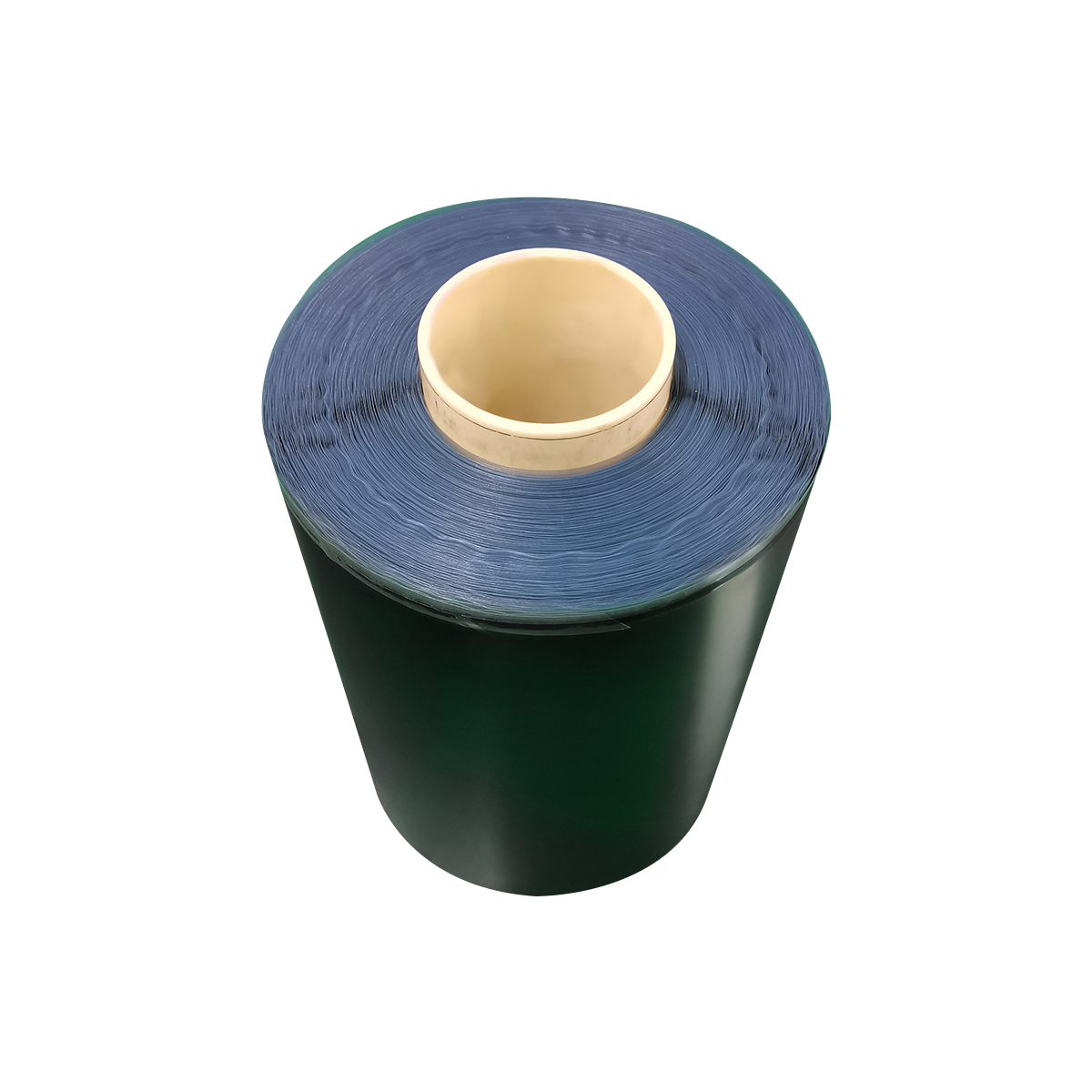

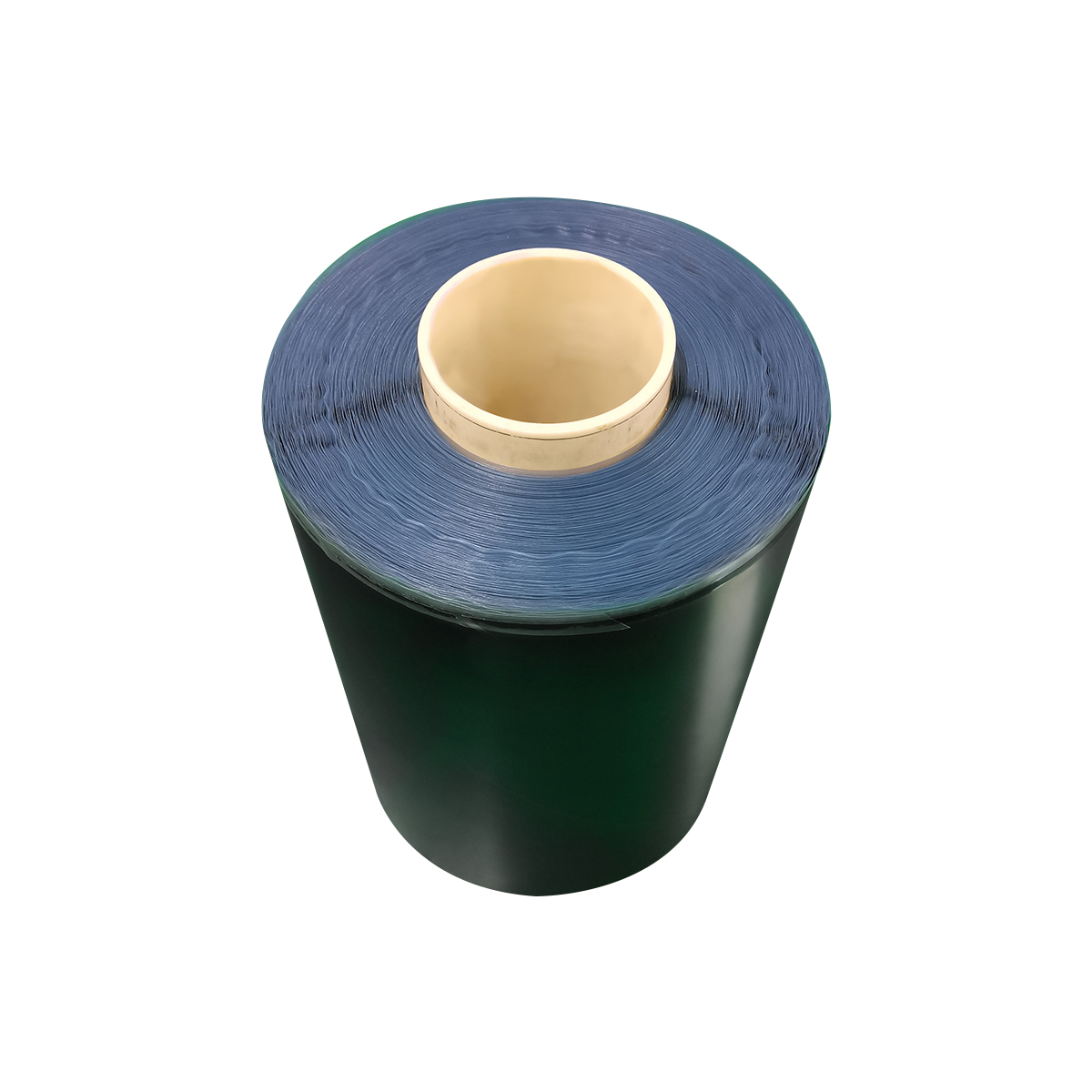

The core of 3D glasses lens lies in their high light transmittance and precise optical performance, which are primarily determined by the materials used and the manufacturing process. Currently, mainstream 3D lenses are typically made of polycarbonate (PC) or specialized optical resins. These materials not only provide excellent light transmittance, ensuring image brightness, but also offer excellent impact resistance, effectively protecting the lenses from damage during daily use.

To enhance the performance and durability of lenses, multiple functional coatings are added during the manufacturing process. The two most important are:

Anti-reflection coating (AR coating): This coating effectively reduces reflections and glare on the lens surface, making images clearer and brighter, significantly enhancing the viewing experience.

Hard coating: This scratch-resistant and abrasion-resistant coating increases the hardness of the lens surface, making it less susceptible to scratches during daily use and thus extending the life of the glasses.

This combination of materials and processes forms the foundation of high-quality 3D lenses, allowing users to enjoy a long-lasting and durable product while enjoying the feast of 3D vision. As a leader in the industry, our company occupies 46,000 square meters of land, with 80,000 square meters of construction space. With four titanium frame production lines and 60 imported injection molding machines, we possess strong production capacity, capable of manufacturing high-quality eyewear in a variety of materials. We have a team of over 300 employees, 20% of whom are dedicated to R&D, encompassing material development, design, mold development, and plate production. This solid foundation ensures continuous product innovation.

3D Lens Selection and Maintenance Guide

Choosing the right pair of 3D glasses and properly caring for them can significantly enhance your viewing experience. Here are some practical purchasing and maintenance tips:

Purchasing Guide

Determine Technology Compatibility: 3D technology on the market is primarily categorized as polarized or active shutter. Before purchasing, be sure to confirm the technology used by your 3D display device (such as a TV, projector, or cinema) and select compatible 3D glasses.

Focus on comfort: Lightweight and comfortable glasses are crucial when wearing glasses for extended periods of time. We recommend lightweight, ergonomically designed frames to reduce pressure on the bridge of your nose and ears.

Focus on optical performance: High-quality lenses should have high light transmittance to ensure accurate brightness and color. Also, inspect the lenses for obvious scratches or blemishes, which can directly affect viewing quality.

Maintenance Guide

Proper Cleaning: When cleaning lenses, use a dedicated eyeglass cleaning cloth or a microfiber cloth to gently wipe. If the lenses are stained, spray them with a professional eyeglass cleaning solution before wiping. Never use clothing or other rough cloths to avoid scratching the lenses.

Avoid high temperatures: High temperatures (such as in a car under direct sunlight) can damage the lens coating and even cause them to warp. When not in use, store the glasses in a dry, cool place.

Proper Storage: To prevent scratches, store your 3D glasses in a dedicated case. Avoid storing them with other hard objects, such as keys or cell phones.

Following these tips will make it easier to choose the right pair of 3D glasses and keep them in top condition, ready for a breathtaking 3D viewing experience. Our products are exported to the United States, Europe, Japan, South Korea and other markets, winning the trust and recognition of global users.

Search

Search EN

EN English

English Deutsch

Deutsch Français

Français Español

Español italiano

italiano cn

cn jp

jp kr

kr