Impact-resistant PC coated sun lens is made of high-strength polycarbonate (PC) as the substrate and integrated with multi-layer functional coating technology. It is a new type of sun lens that takes into account both protective performance and optical experience. Its core advantage lies in the organic combination of the inherent impact toughness of PC material and the multi-dimensional protection function of the coating layer (UV blocking, glare suppression, surface strengthening, etc.). It can not only cope with potential collision risks in sports or daily scenes, but also ensure clear vision and color restoration through optimized optical design, providing reliable protection for eye needs in different environments.

Product Features

Impact-resistant structural design

The PC substrate reinforced with molecular chains has excellent impact toughness and can resist splashing particles and accidental collisions in high-speed movement. The material properties meet the requirements of international protection standards, and lightweight design is achieved while maintaining structural stability.

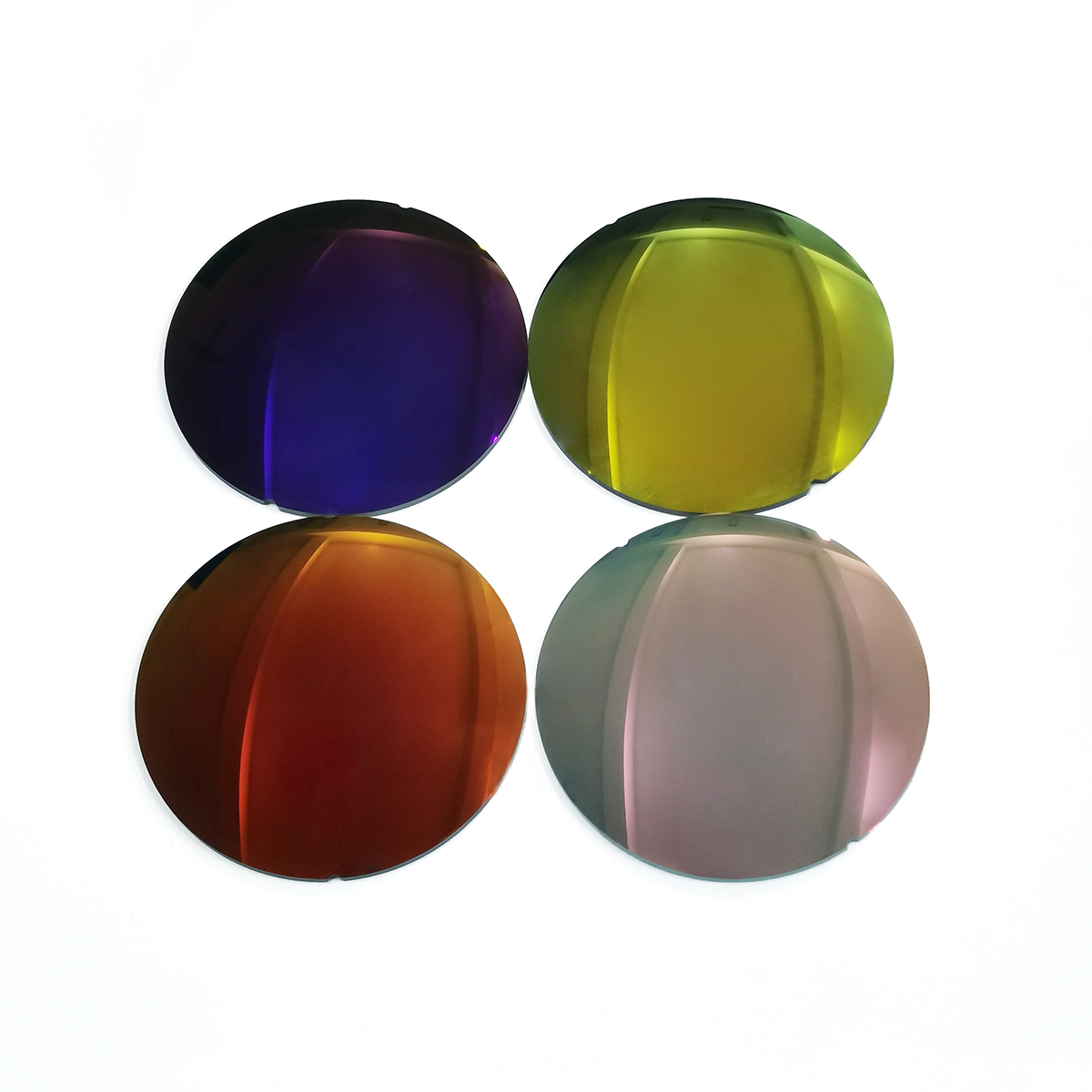

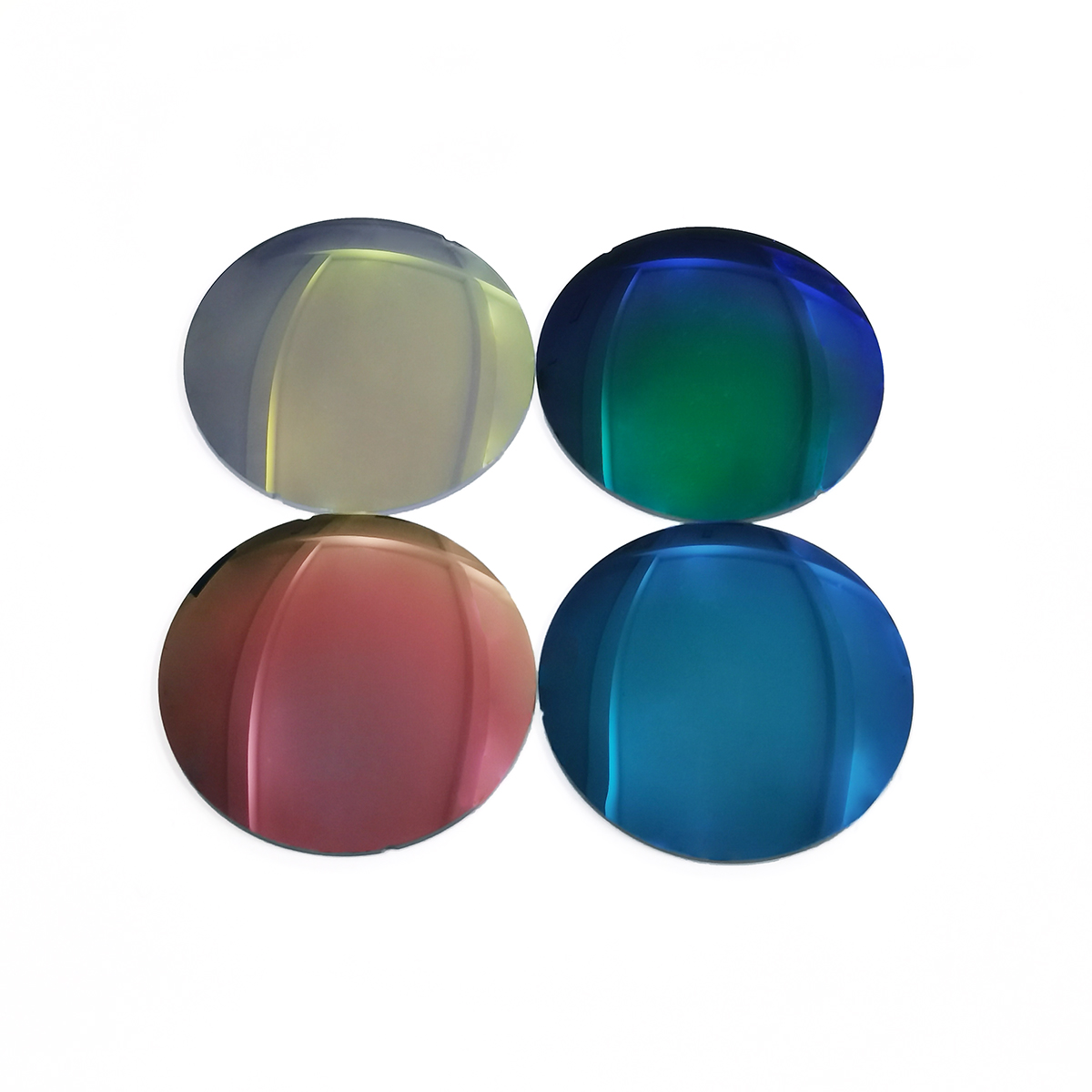

Multi-layer composite coating system

The protection system is constructed through vacuum ion plating technology: the outermost layer is a hardened coating to improve the surface hardness; the middle layer integrates UV400 absorber, which can effectively block the full-band ultraviolet radiation; the inner layer is an anti-reflective coating to reduce the reflectivity of the front and rear surfaces of the lens and reduce glare interference.

High-definition optical performance

The aspheric optical curved surface design is combined with the refractive index matching technology of the coating layer to effectively control the dispersion phenomenon and ensure the consistency of the central and peripheral fields of vision. The substrate itself has high light transmittance, and the anti-reflection treatment of the coating layer is used to achieve natural color restoration and clear imaging.

Enhanced environmental adaptability

The weather resistance of the lens is improved through surface chemical modification: maintaining dimensional stability in high temperature environments, preventing hydrolysis of the coating layer in humid environments, and resisting the erosion of daily chemicals (such as sweat and oil). The edge structure treated with special processes can reduce stress concentration and delay material aging.

Ergonomic adaptation

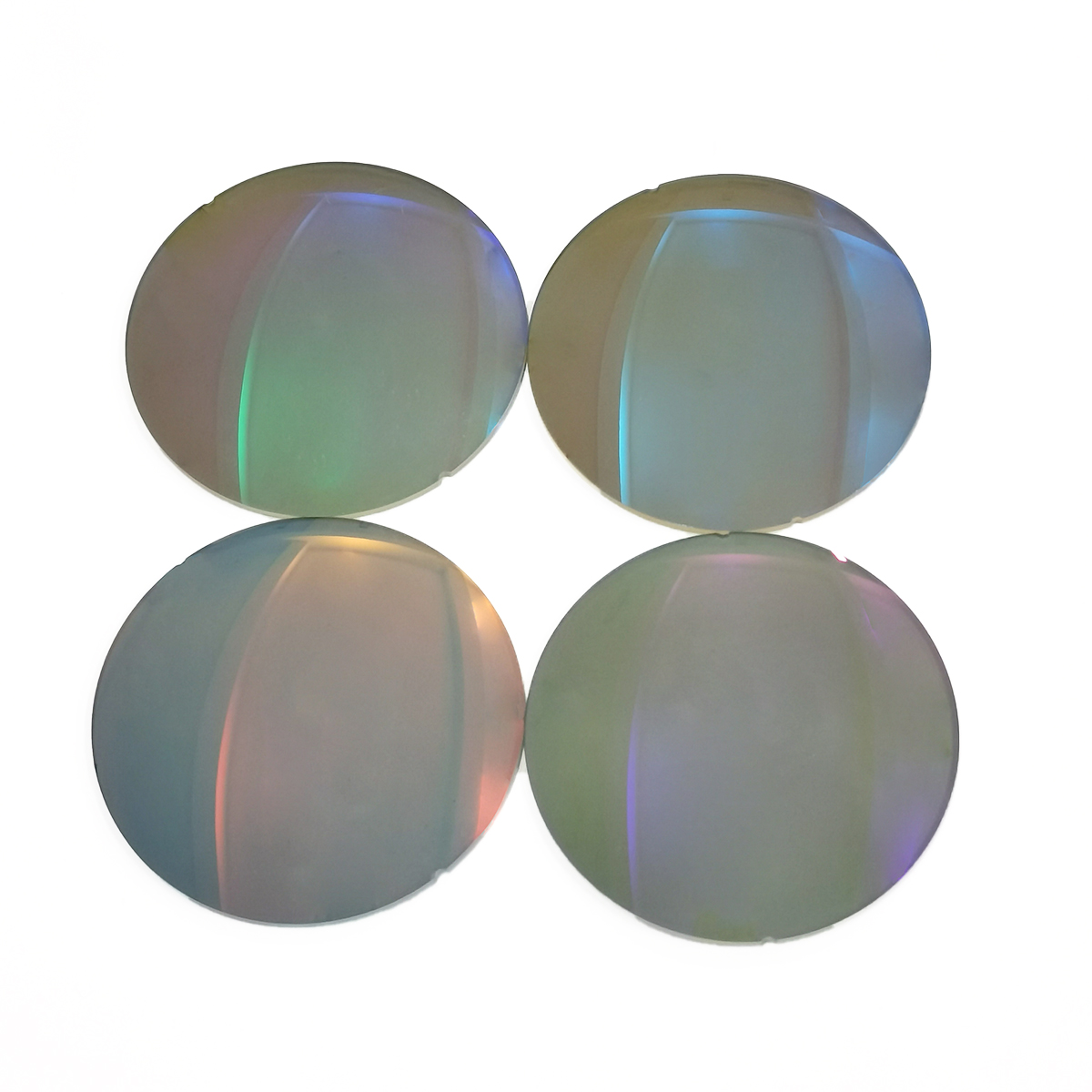

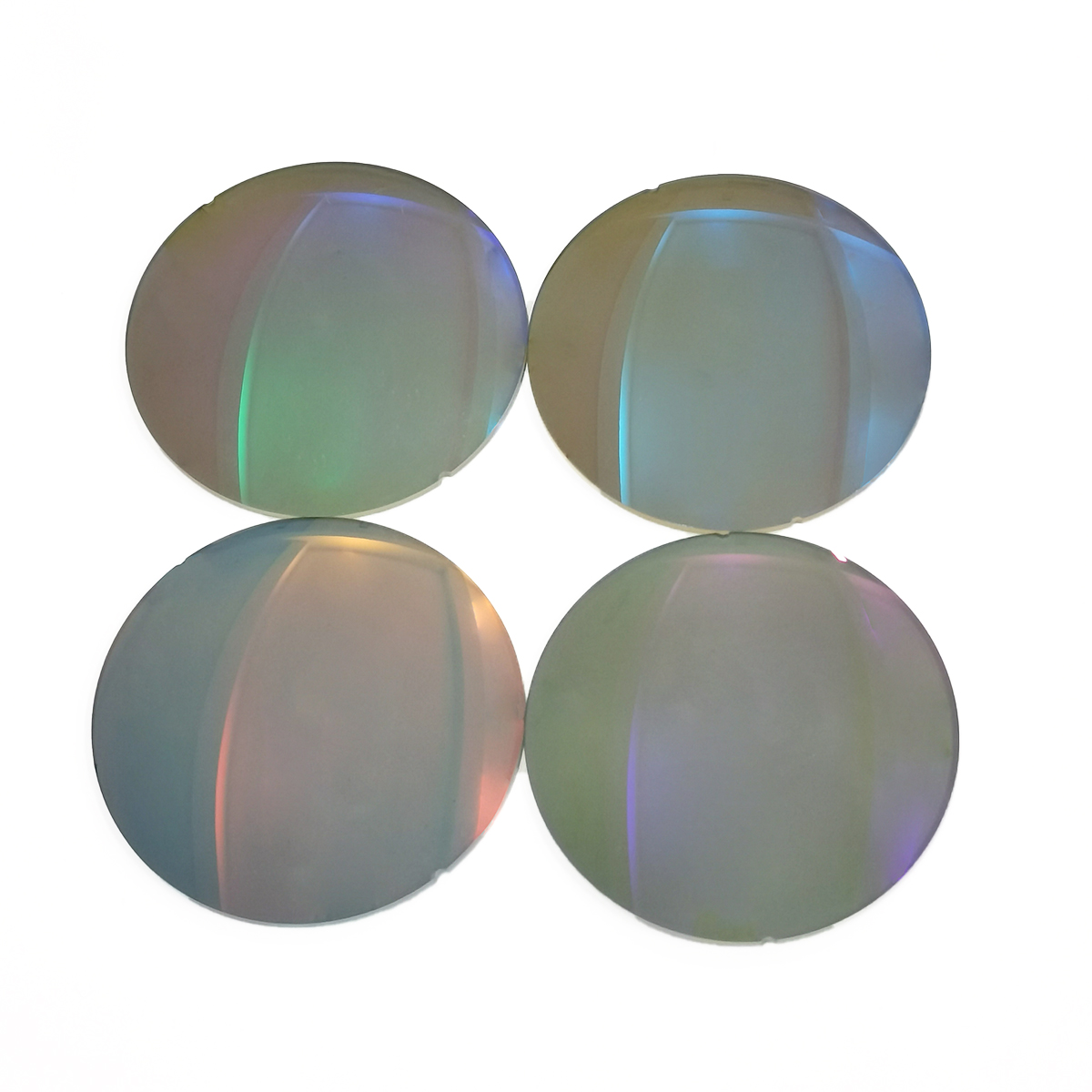

The thickness and curvature of the lens are optimized to adapt to the mainstream frame structure. The lightweight characteristics (density of about 1.2g/cm³) reduce the sense of oppression during long-term wear, and the low friction coefficient of the coating layer improves wearing comfort. The special coating process can achieve a gradient dyeing effect to meet the light attenuation requirements of different scenes.

Full life cycle protection

Through the synergistic effect of the coating layer, the three-dimensional protection of the lens is achieved: the anti-scratch coating can withstand the mechanical stress caused by daily wiping, the anti-fouling coating reduces the adhesion of fingerprints and oil stains, and the anti-static coating reduces dust adsorption. This multi-level protection system significantly extends the effective service life of the lens.

Application scenarios

Suitable for outdoor sports such as skiing, cycling, and mountaineering, it can effectively deal with high-speed airflow, ultraviolet radiation, and potential collision risks; at the same time, it meets the protection needs of daily driving, travel, and other scenes, maintaining visual clarity in strong light environments and reducing eye fatigue.

Search

Search EN

EN English

English Deutsch

Deutsch Français

Français Español

Español italiano

italiano cn

cn jp

jp kr

kr