TAC polarized lens are not simply tinted lenses; they are constructed from a laminated composite material, with the core polarizing filter layer being the most critical.

TAC stands for Tri-Acetate Cellulose. This lightweight, flexible, and durable material allows TAC polarized lens to maintain excellent optical performance while being lighter and more comfortable to wear. Compared to traditional glass or ordinary plastic lenses, TAC polarized lens are not only more shatter-resistant but also withstand general impact, providing better eye protection.

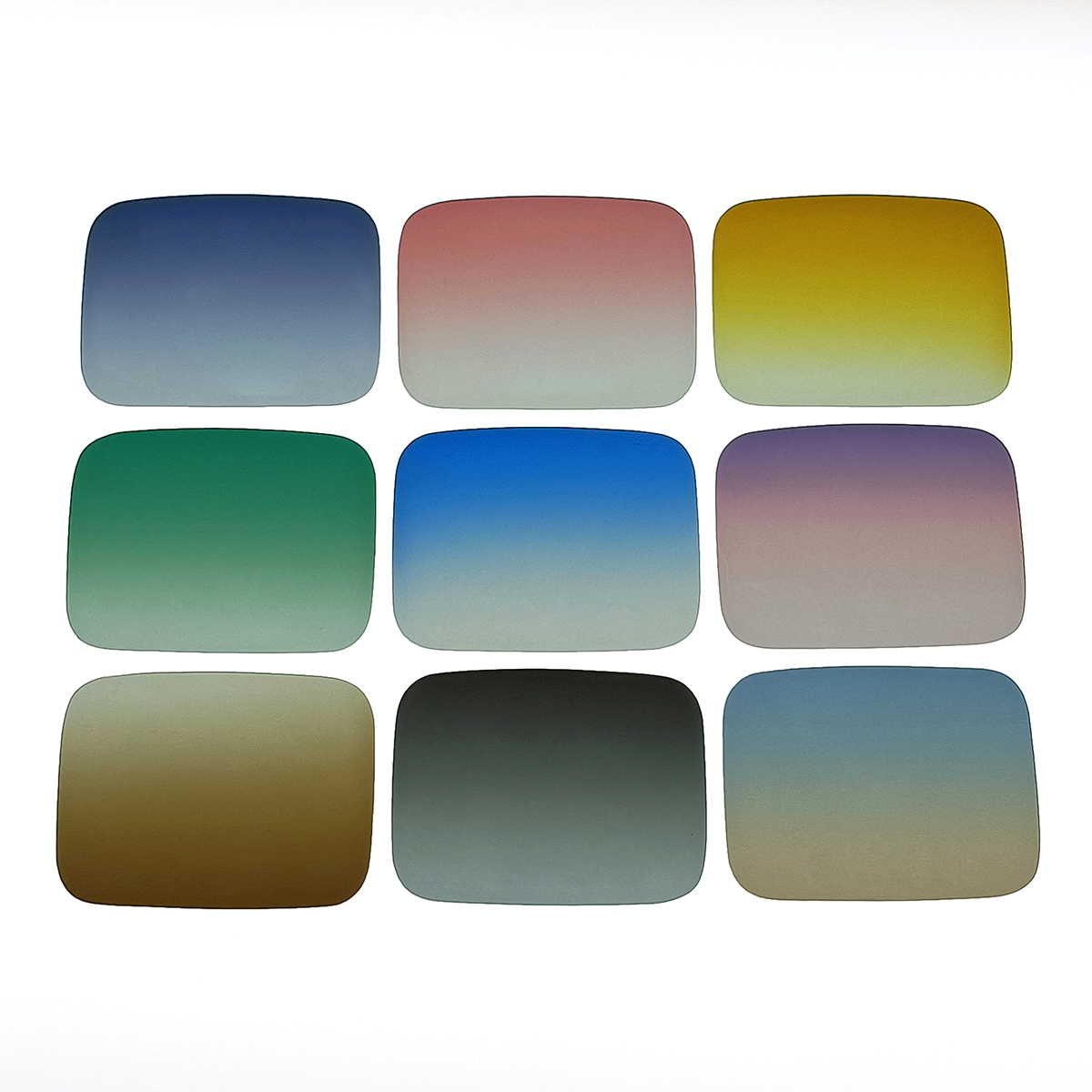

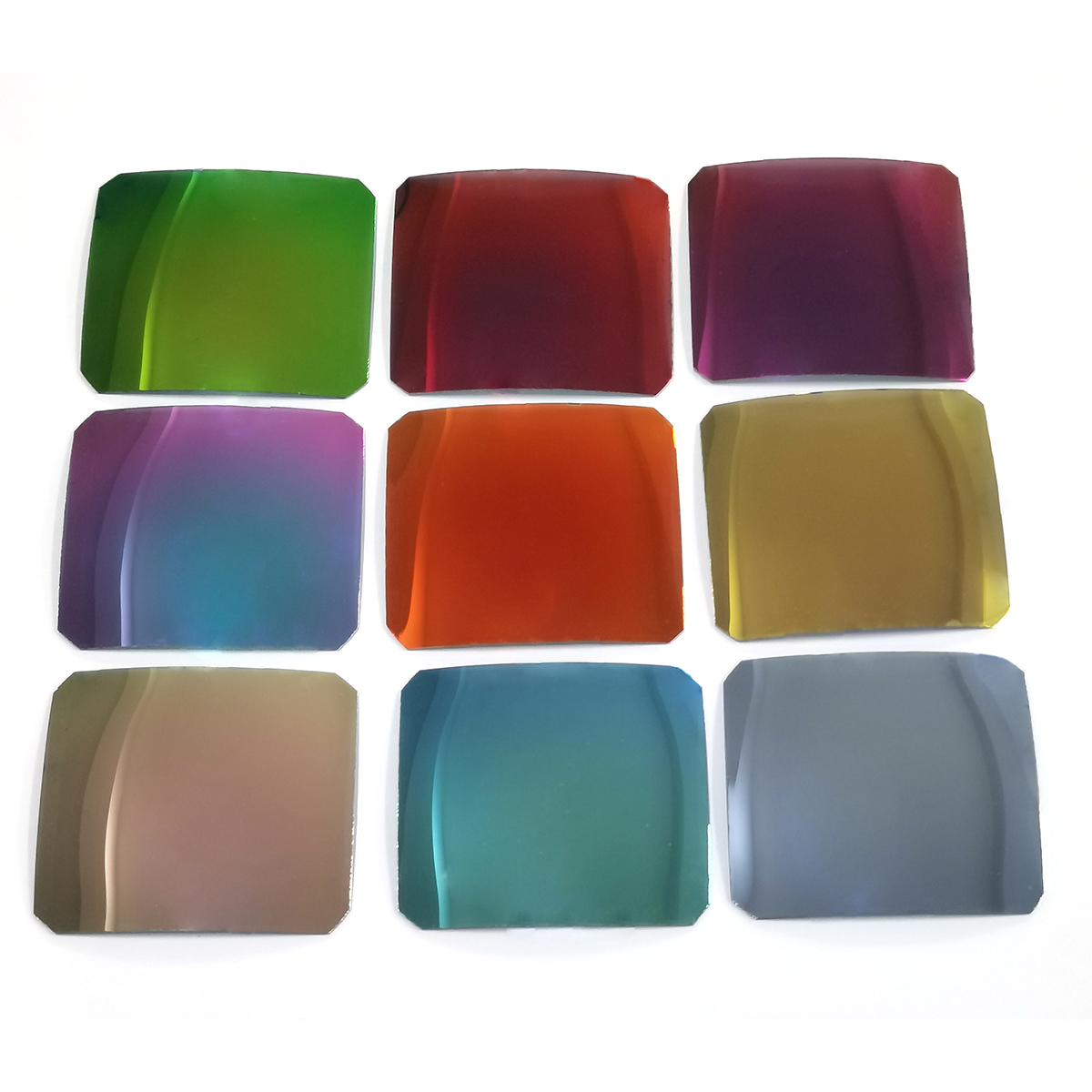

In addition, the multi-layer construction includes a UV protection layer (reaching UV400 standards), an abrasion-resistant layer, and an impact-resistant coating. These processes ensure that TAC polarized lens offer excellent clarity and durability.

How it works: Reducing glare for a clearer view

In sunlight, strong reflections often occur on water, snow, or wet roads. This glare is called "glare," and it is primarily caused by polarized light in a specific direction.

The core principle of TAC polarized lens is to block horizontally polarized light. The polarizing layer in the lens acts like a set of "blinds," allowing only perpendicular light to enter while blocking out glare caused by reflections.

This filtering method reduces glare by over 90%, resulting in higher visual contrast and more natural, clearer colors. Whether observing schools of fish underwater or discerning the subtle undulations of a snowy slope, you can see more clearly.

Why choose our TAC polarized lens?

Our TAC polarized lens are widely used in sunglasses, driving glasses, sports goggles, and other products, and are popular in many countries and regions.

Our company occupies 46,000 square meters, with 80,000 square meters of construction space, and specializes in the research and development and production of optical eyewear, sunglasses, reading glasses, and other products. To ensure lens quality, we are equipped with four titanium frame production lines and 60 imported injection molding machines, providing reliable support for the production of eyewear made of various materials.

Our R&D team, comprising approximately 20% of our total employees, covers a wide range of areas, including material research and development, design, molds, and plate manufacturing. This ensures that our TAC polarized lens achieve industry-leading levels of optical precision, curvature control, and wearing comfort. Thanks to our consistent quality, our products have been exported to markets such as the United States, Europe, Japan, and South Korea, and have been well-received by customers.

How to identify and maintain TAC polarized lens?

Identification method:

Mobile screen test: Place the lens in front of the phone screen and rotate it. If the lens color darkens or even turns black, it indicates polarization.

Overlap test: Overlap two polarized lenses and rotate them. When one of them is rotated 90 degrees, almost no light is transmitted.

Daily care:

Cleaning: Use a dedicated lens cleaning solution and a soft glasses cloth. Avoid wiping with the corners of clothing or rough tissues to avoid scratching the lenses.

Storage: When not wearing, store the lenses in a case to avoid contact with hard objects and keep them dry.

Avoid high temperatures: Avoid prolonged storage in high-temperature environments, such as on a car dashboard, to prevent damage to the lens' performance and lifespan.

Search

Search EN

EN English

English Deutsch

Deutsch Français

Français Español

Español italiano

italiano cn

cn jp

jp kr

kr