This Nylon UV400 Polarized Tinted Sun Lens uses aviation-grade nylon substrate and precision optical coating design to provide all-round visual protection for outdoor and professional scenes. The ultra-thin thickness of 1.8-2.0mm is both lightweight and impact-resistant (certified by ANSI Z87.1 and CE EN166), and the diameters of 70/73/75mm are suitable for mainstream frames. Built-in UV400 ultraviolet absorption layer and dynamic polarizing filter film can block more than 99% of UVA/UVB rays and eliminate 85% of horizontal glare. It is suitable for driving, skiing, fishing and other scenes, taking into account optical clarity and durability.

Core Features

Ultra-light nylon substrate and structural advantages

Using special transparent polyamide material, the density is only 1.01g/cm³, which is 50% lighter than traditional resin lenses (single lens 22-26g). 1.8-2.0mm thickness passed the international drop ball test, with 30% better impact resistance than PC lenses, and maintains optical stability in -20℃ to 60℃ environment, avoiding deformation and brittleness, suitable for high-risk sports.

Full spectrum UV400 protection

Integrated with multiple layers of UV absorbers, completely blocks harmful rays below 400nm, in line with ANSI Z80.3 and AS/NZS 1067 standards. The protective layer is bonded to the substrate molecules, and the blocking rate is still over 99.2% after 1000 hours of aging test, which is suitable for strong UV environments.

Dynamic polarized light filtering

Vertical directional polarized film filters 85%-90% horizontal glare, improves road sign contrast by 30% when driving, and reduces nighttime glare by 50%. Vacuum hot pressing bonding technology avoids edge debonding and ensures long-term stability.

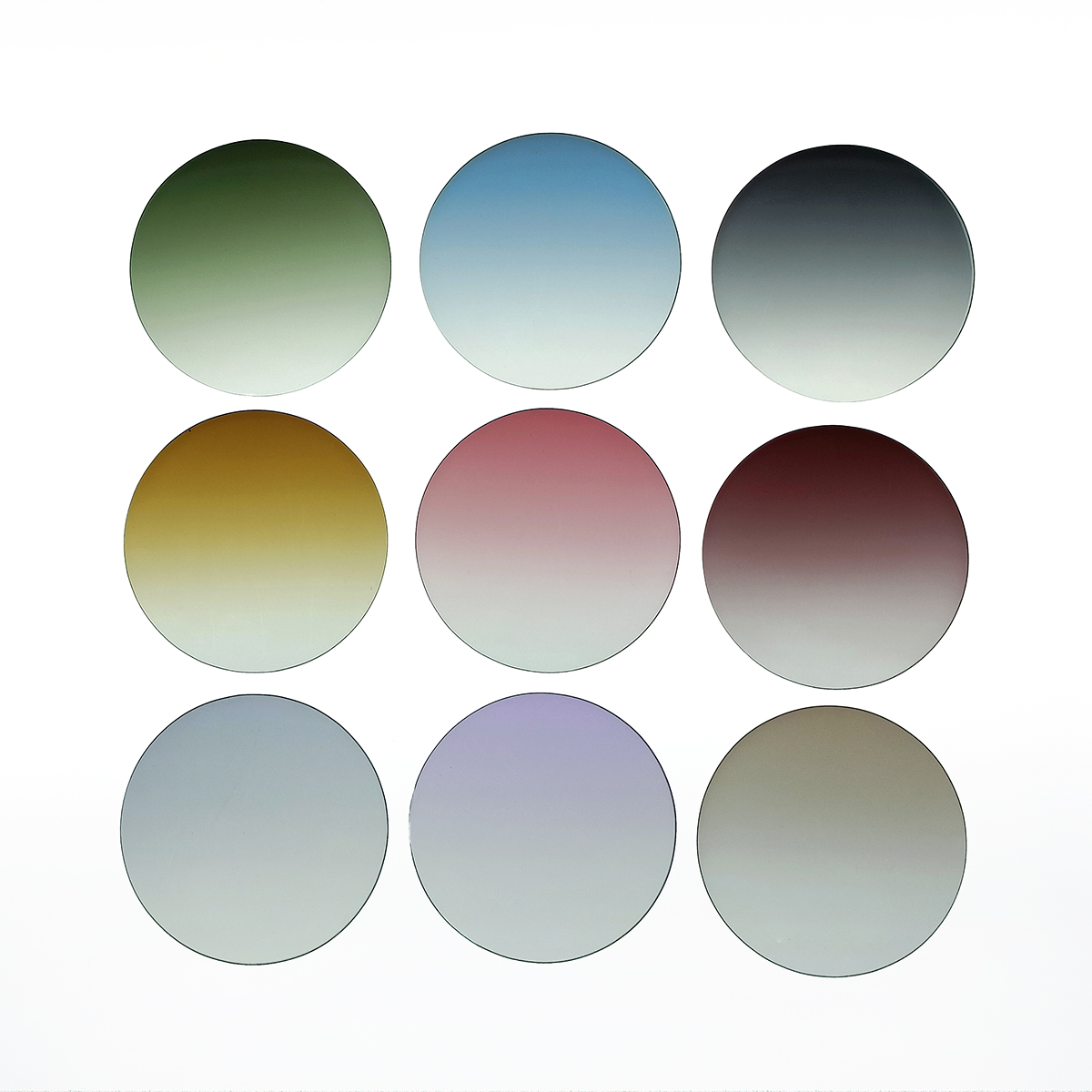

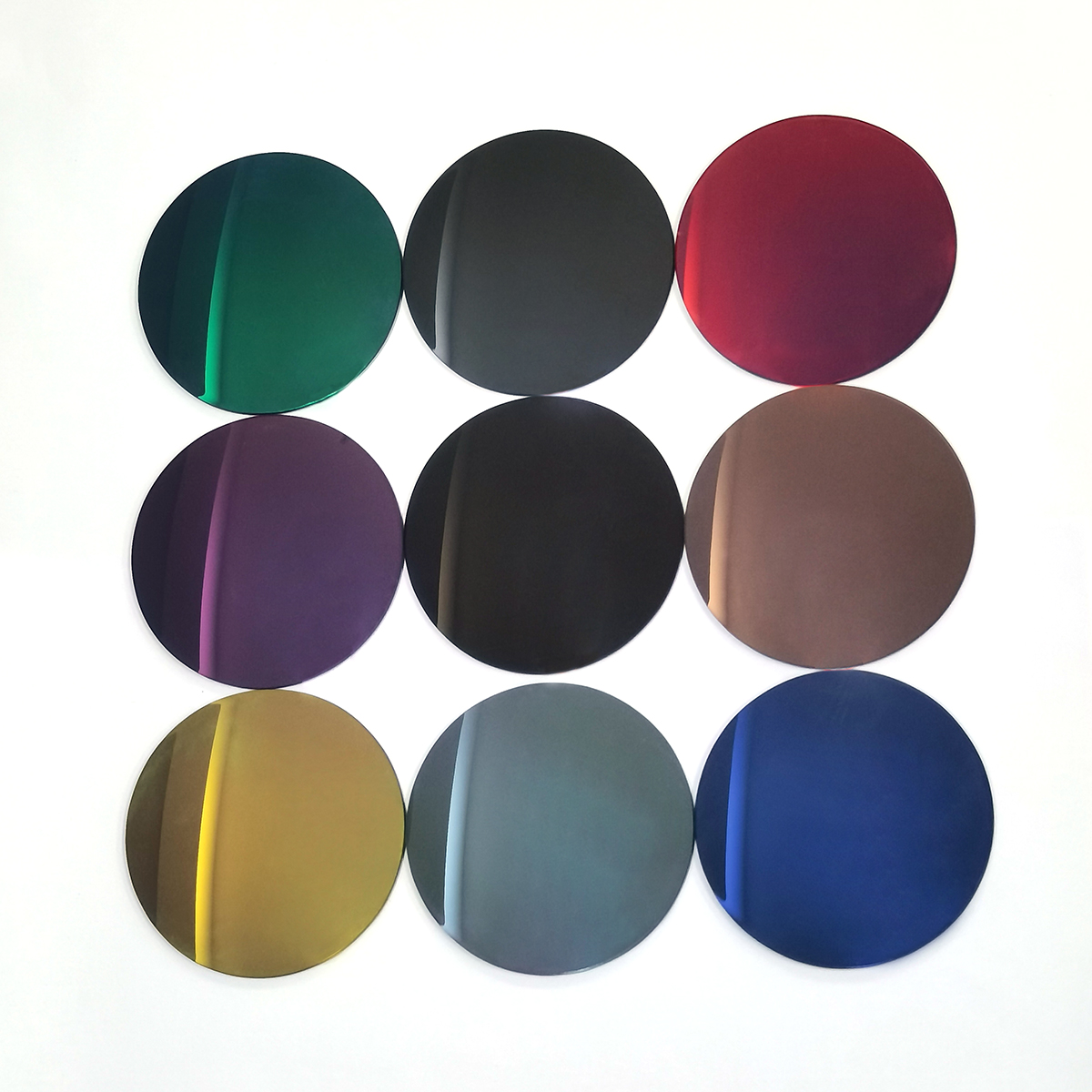

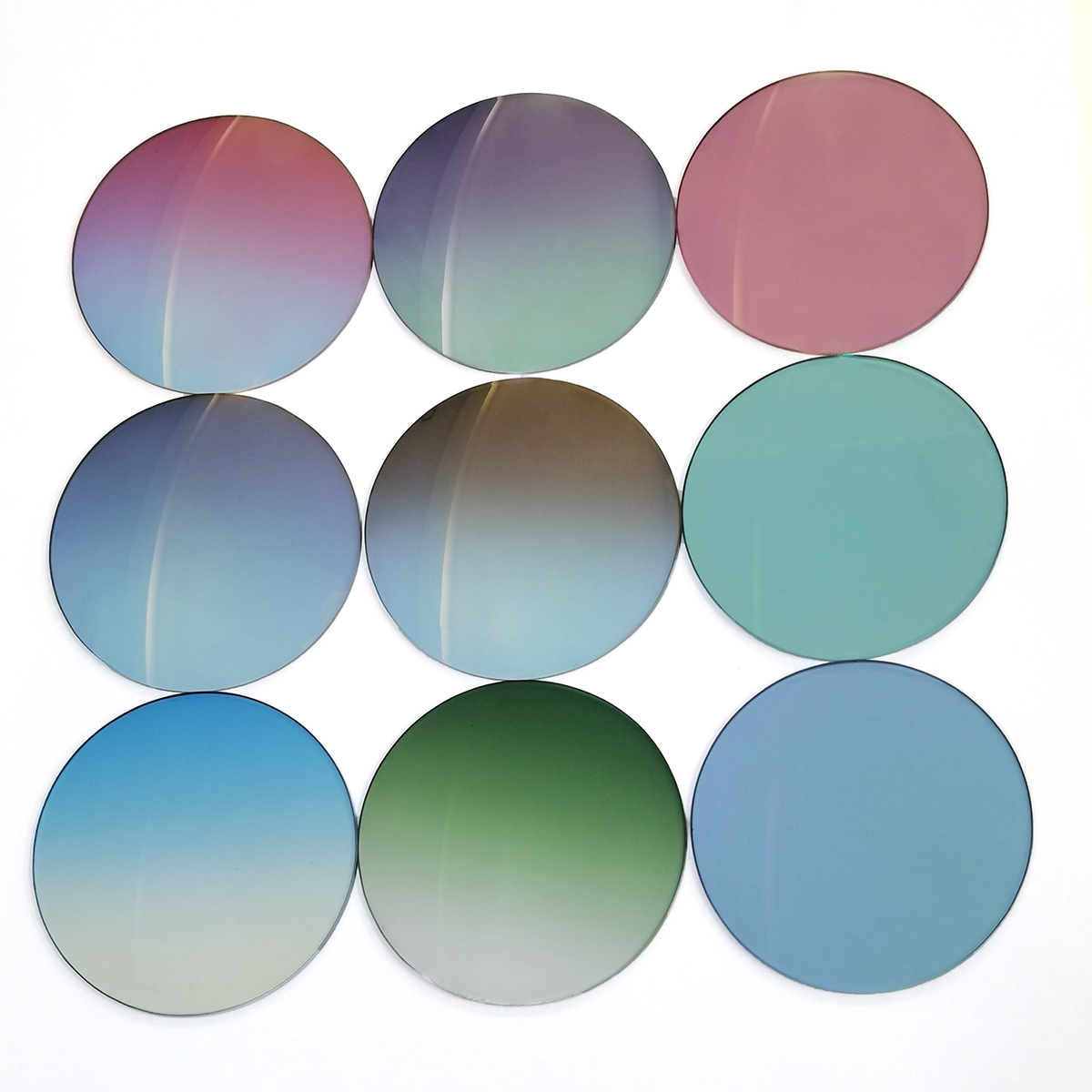

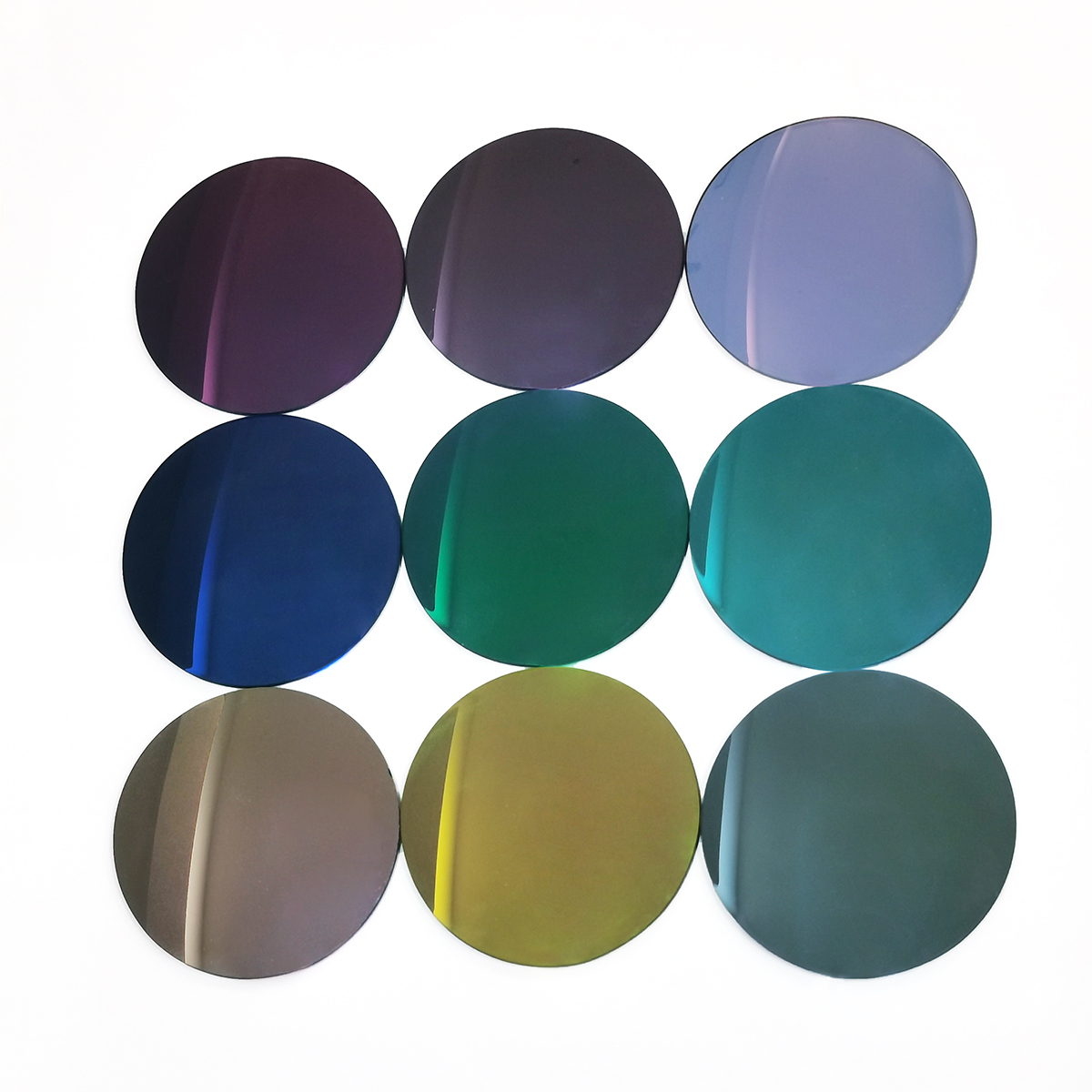

Smart dyeing and optical optimization

Vacuum ion dyeing forms nano-color scale: gray (VLT 12-18%) preserves natural color, amber (VLT 18-25%) enhances the contrast of medium and long wave light, and green (VLT 20-28%) optimizes depth of field. Abbe coefficient 52, reducing dispersion and visual fatigue.

Composite surface treatment

Seven-layer composite coating: 3H scratch-resistant, impact-resistant AR, oleophobic and hydrophobic (contact angle > 110°), anti-static and other functional layers, wear-resistant, anti-fouling and waterproof, maintaining a clear field of vision.

Typical application scenarios

Extreme sports: 73mm diameter is suitable for curved frames, reducing 80% side glare when skiing, passing EN166:2001 anti-fog test, and resistant to -30℃ to 25℃ environment.

Water fishing: The polarizing layer filters the reflection of the water surface, and the 75mm wide field of view helps observe fish schools at a depth of 3 meters and enhances environmental perception.

Urban commuting: 70mm diameter is suitable for Asian faces, gray lenses attenuate LED blue light, and antistatic layer reduces dust absorption, suitable for daily use and cycling.

Industrial protection: 1.8mm thickness complies with ANSI Z87.1, can be combined with helmets and masks to provide all-round impact protection.

High-end fashion: Multiple specifications support gradient and mirror coating customization, balancing aesthetics and performance.

The lens optimizes 400-700nm visible light transmission, improves color sensitivity by 15%, and has passed EU R43 certification. The lightweight and BPA-free features take into account both functionality and sustainability, providing a reliable visual solution for professional and daily scenarios.

Search

Search EN

EN English

English Deutsch

Deutsch Français

Français Español

Español italiano

italiano cn

cn jp

jp kr

kr